Hydrothermal synthesis autoclave reactor Introduction

The hydrothermal synthesis reactor is a reactor provided for synthesizing chemical substances under certain temperature and certain pressure conditions. It is widely used in scientific research experiments in new materials, energy, environmental engineering and other fields, and is a commonly used small reactor for scientific research in teaching and scientific research units in colleges and universities.

Hydrothermal synthesis autoclave reactor working principles

The hydrothermal synthesis reactor adopts an aqueous solution as the reaction system under certain temperature and pressure conditions, and uses the high-temperature and high-pressure aqueous solution to dissolve those substances that are insoluble or insoluble under atmospheric conditions, or react to generate dissolved products of the substances. The temperature difference caused by convection to form a supersaturated state and precipitation of growing crystals.

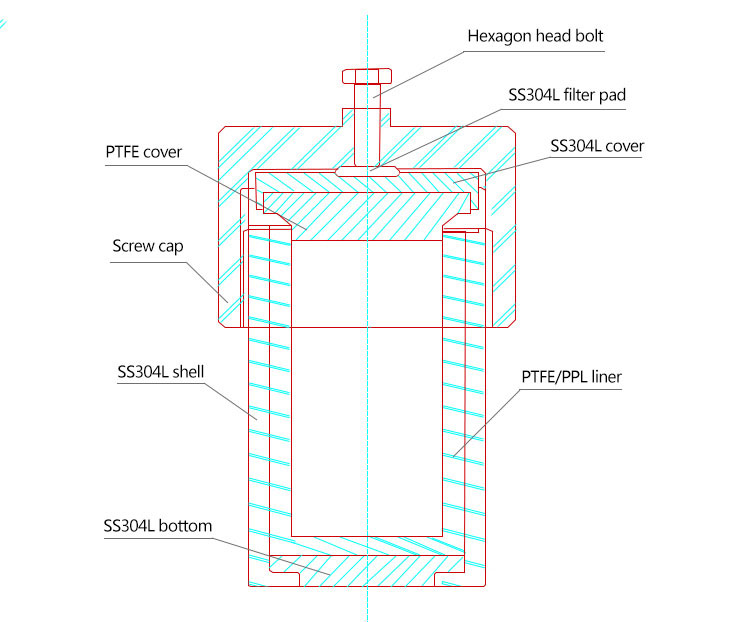

Structure And Performance of Hydrothermal synthesis autoclave reactor

The hydrothermal synthesis reactor is mainly composed of two parts: the kettle body cover and the inner liner. The inner liner mainly includes three types: PFA inner liner, PPL inner liner and teflon liner:

Kettle cover: to ensure that the medium and mixing parts are completely sealed

Liner:

The PFA inner tank is resistant to high temperature. The temperature measured at the factory can reach 280°C. The recommended actual use temperature is 260°C. Such a temperature can greatly extend the service life of the PPL inner tank.

The PPL liner is resistant to high temperature. The temperature measured at the factory can reach 300°C. The actual temperature is recommended to be 280°C. Such a temperature can greatly extend the service life of the PPL liner.

PTFE liner, high temperature resistance, the temperature measured at the factory can reach 220°C, and the actual operating temperature is recommended to be 180°C, which can greatly extend the service life of the PPL liner.

Hydrothermal synthesis autoclave reactor advantages

1. The hydrothermal synthesis kettle is made of high-quality stainless steel. The sealing of the kettle body and the kettle cover adopts a durable and reliable line sealing structure, and the sealing effect is stable and leak-free for a long time.

2. It can quickly and non-destructively dissolve samples that are difficult to dissolve under normal conditions, as well as samples containing volatile elements after heating and increasing pressure.

3. The external heating method is adopted to reduce the volume, and it is advantageous for multiple reaction kettles to be at the same reaction operating temperature (such as placing multiple reaction kettles in an oven for heating).

4. High temperature resistance: -200℃~240℃, pressure: 0~6MPa.

5. The lined material is made of teflon, which has the characteristics of acid and alkali resistance.

Hydrothermal synthesis autoclave reactor application

The teflon lined hydrothermal synthesis autoclave reactor can be used in polymerization reactors, high-pressure digestion tanks, hydrothermal reactors, pressure-dissolving bombs, and digestion tanks. It is a small reactor commonly used in chemical laboratories. It can be used for small-dose synthesis reactions. It can also use strong acid in the tank. Or strong alkali and high temperature and high pressure airtight environment to achieve the purpose of quickly digesting insoluble substances.

The operation of hydrothermal synthesis autoclave reactor

1. Pour the material into the teflon lined.

2. Then put the teflon lined into the stainless steel jacket, add a gasket, cover the kettle cover and tighten it.

3. The hydrothermal synthesis reactor is placed in the drying oven, and the temperature rises and heats up, and the temperature can be raised in stages according to requirements. (The temperature does not exceed 220, and the pressure does not exceed 3Mpa).

4. After the reaction is over and the temperature of the hydrothermal synthesis reactor drops to room temperature, twist the lid of the kettle to loosen and take out the inner lining.

5. The hydrothermal synthesis reactor crystallization kettle should be cleaned after use to prevent rust.

Parameter

Model | Volume (ml) | Pressure | Heating/cooling rate | Working Temperature |

KH-25 | 25 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-50 | 50 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-100 | 100 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-150 | 150 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-200 | 200 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-300 | 300 | ≤3 Mpa | 5℃/min | ≤230°C |

KH-500 | 500 | ≤3 Mpa | 5℃/min | ≤230°C |

Model | Volume (ml) | Pressure | Heating/cooling rate |

KH-25 | 25 | ≤3 Mpa | 5℃/min |

KH-50 | 50 | ≤3 Mpa | 5℃/min |

KH-100 | 100 | ≤3 Mpa | 5℃/min |

KH-150 | 150 | ≤3 Mpa | 5℃/min |

KH-200 | 200 | ≤3 Mpa | 5℃/min |

KH-300 | 300 | ≤3 Mpa | 5℃/min |

KH-500 | 500 | ≤3 Mpa | 5℃/min |