The heater chiller circulator is our new product. It can provide both heating and cooling, so it can be used for supporting equipment for various products, such as rotary evaporator, glass reactor, short path distillation, etc.

Heater chiller circulator introduction

In the whole system of the GDX series Heater chiller circulator, the liquid circulation is sealed, and the system has an expansion vessel, which is mechanically connected, does not participate in the liquid circulation, and is insulated from the liquid circulation. Regardless of whether the temperature of the liquid cycle is high or low, the medium in the expansion vessel is less than 60 degrees. The whole liquid cycle is a closed system, no water vapor will be inhaled at low temperatures, oil mist will not be inhaled at high temperatures, and the heat transfer oil has a wide working temperature.

Heater chiller circulator Structure

A heater chiller circulator mainly includes four parts: a digital display instrument, built-in compressor, air inlet, and liquid filling port.

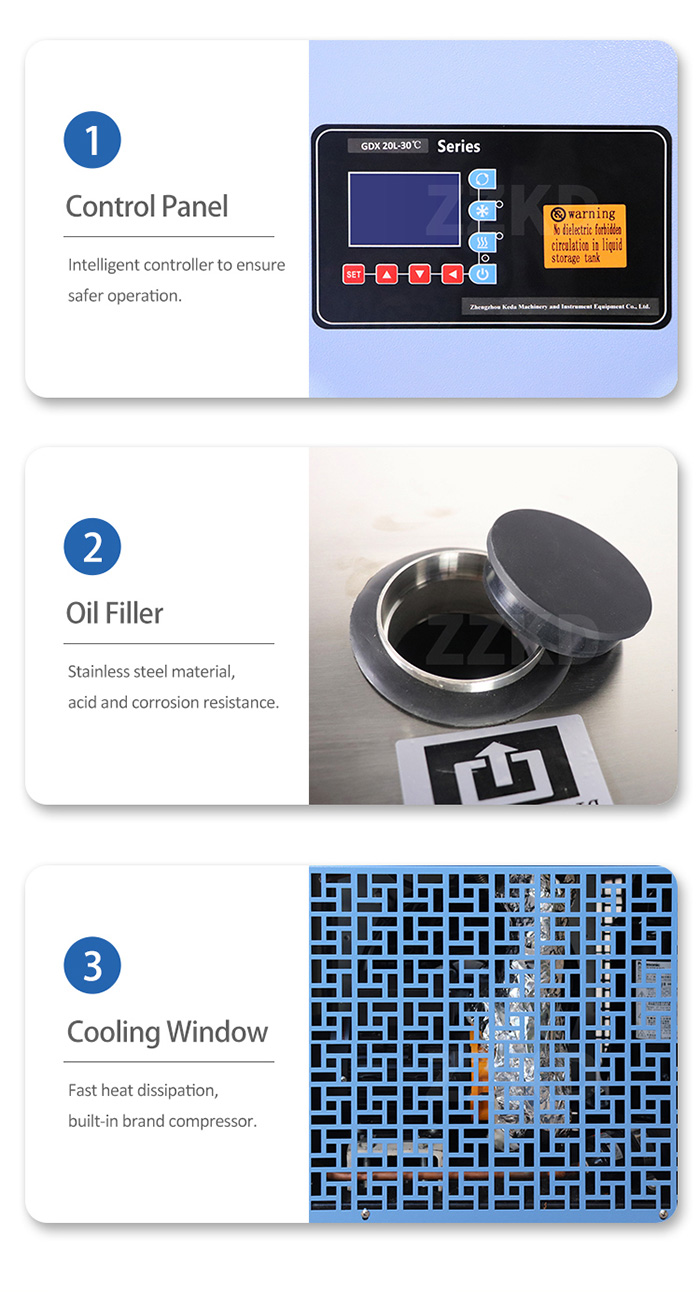

Digital display instrument

LED LCD screen, intelligent controller, parameters are clear at a glance, easy to operate.

Heater chiller circulator

Imported air-cooled hermetic compressor unit refrigeration, computer intelligent refrigeration control system.

Inlet

Shutter design, made of anti-corrosion and corrosion-resistant materials

Liquid filling port

Stainless steel material, corrosion-resistant, and easy to clean.

Heater chiller circulator features

(1) Equipped with a heating and cooling integrated container, the heat exchange area is large, the heating and cooling rates are fast, and the demand for heat transfer oil is relatively small.

(2) It can realize continuous temperature rise and fall, and the compressor technology is used to operate under high temperatures and high pressure. The compressor can be directly turned on for refrigeration from 199 degrees, which greatly improves the cooling rate and saves test time and energy.

(3) The whole cycle is airtight, there is no oil mist volatilization at high temperatures, and the heat transfer oil is not easy to be oxidized and browned; it is not easy to absorb water vapor in the air at low temperatures; prolonging the service life of heat transfer oil.

(4) This equipment has various safety guarantee functions, such as self-diagnosis function, refrigerator overload protection, high-pressure pressure switch, overload relay, thermal protection, high-pressure protection device of circulation system during high-temperature heating, etc., to fully guarantee the safety of use;

(5) Wide working temperature range, with heating and cooling function at the same time, the maximum temperature range: -120~200℃.

Heater chiller circulator application

Heater chiller circulator can provide a temperature-controlled, uniform temperature environment, widely used in petroleum, chemical, electronic instruments, physics, chemistry, biological engineering, medicine and health, life sciences, light industrial food, physical property testing and chemical analysis research departments, colleges and universities, enterprise-quality inspection and production departments.

Heater chiller circulator used for different equipment

(1) Reactor equipment supporting

The reactor equipment uses the heat transfer medium in the heating reaction kettle jacket to indirectly transfer heat energy to the materials in the kettle to achieve the purpose of controlling the temperature of the reaction materials, and the high temperature can reach 350 °C. The heater chiller circulator can be used with all kinds of reactor equipment, including glass reactors, double-layer glass reactors, stainless steel reactors, enamel reactors, etc.; in the process of temperature control, the equipment can choose to control the temperature of the jacket Or two control methods to control the temperature of the material, which can be switched according to the reaction requirements.

(2) Supporting the use of liquid storage tank

The liquid storage tank is equipped with a three-layer thermal insulation liquid storage tank with a jacket and a thermal insulation layer. It has the functions of heating, thermal insulation, stirring, etc. The needs of the development of the pharmaceutical industry.

(3) Fermentation tank supporting the use

The reaction process of the fermenter has a great influence on the temperature. Controlling the temperature of the fermenter is beneficial to the speed of various enzyme reactions, changing the synthesis direction of metabolites, and affecting the regulation of microbial metabolism. In order to meet the required temperature requirements, a heater chiller circulator is used in the production to control the temperature of the fermentation tank to provide a suitable temperature to achieve the required temperature and reaction effect.

(4) Practical application of heater chiller circulator in extraction

During extraction, according to the characteristics of the solvent, different temperatures and pressure of dissolution and extraction are selected to realize rapid extraction of solvent heating. Using external temperature control, different heating temperatures and heating time can be set, which further enhances the operability of the system, accelerates the rapid extraction of solvents, saves man-hours, and improves extraction efficiency.

(5)Practical application of heater chiller circulator matching distillation

The heater chiller circulator adopts a temperature control gradient and uses a high and low-temperature integrated machine to control it at different temperatures to achieve the distillation temperature and ensure the condensation effect.

Parameter

Model | Temp. Range (℃) | Heating Power (W) | Circulating Pump Power (W | Flow (L/min) | Lift (m) | Voltage (V) | Current |

GDX-5/10 | -9~199 | 1000 | 166 | 100 | 20 | 6 | 9 |

GDX-5/30 | -30~199 | 1000 | 1800 | 100 | 25 | 6 | 10 |

GDX-10/30 | -30~199 | 2000 | 2900 | 100 | 20 | 6 | 16 |

GDX-20/30 | -30~199 | 3000 | 4300 | 100 | 25 | 6 | 22 |

GDX-30/30 | -30~199 | 4000 | 6400 | 100 | 25 | 7 | 31 |

GDX-50/80 | -80~199 | 6000 | 16400 | 280 | 35 | 11 | 28 |

GDX-100/60 | -60~199 | 9000 | 22000 | 280 | 35 | 11 | 46 |

Model | Temp. Range (℃) | Heating Power (W) | Circulating Pump Power (W |

GDX-5/10 | -9~199 | 1000 | 166 |

GDX-5/30 | -30~199 | 1000 | 1800 |

GDX-10/30 | -30~199 | 2000 | 2900 |

GDX-20/30 | -30~199 | 3000 | 4300 |

GDX-30/30 | -30~199 | 4000 | 6400 |

GDX-50/80 | -80~199 | 6000 | 16400 |

GDX-100/60 | -60~199 | 9000 | 22000 |