Introduction

The fluid bed granulation process efficiently transforms powder particles into uniform, porous granules. Utilizing clean, heated air, the process fluidizes and mixes the particles while simultaneously spraying an adhesive solution. This encourages particle agglomeration. Continuous hot air ensures moisture evaporation, producing high-quality granules consistently.

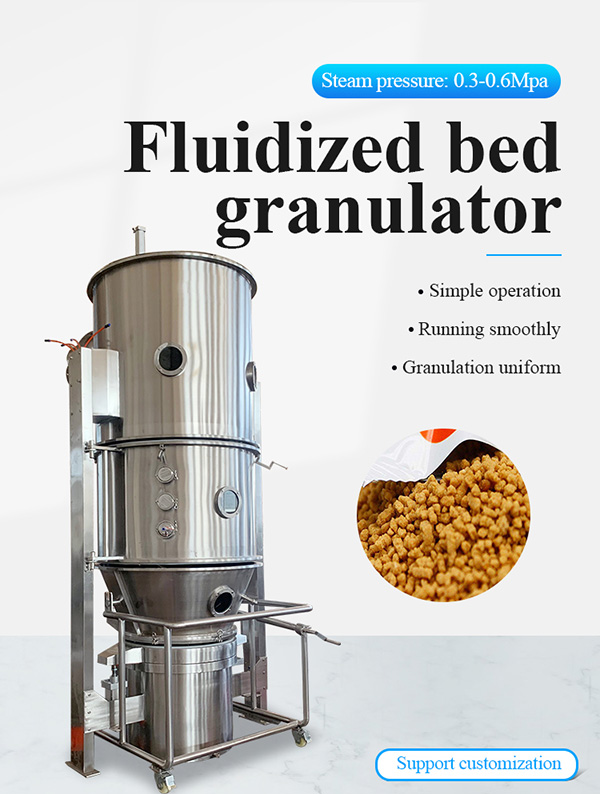

Features of Fluidized Bed Granulator

Enhanced Flow and Dust Reduction: Through powder granulation, the process significantly improves the flowability of the granules while minimizing dust production.

Improved Solubility: The granulation enhances the solubility of the final product, making it more efficient in various applications.

Integrated Process: The fluidized bed granulator combines mixing, granulation, and drying in a single device, known as one-step granulation, simplifying the production process.

Safety Measures: The use of antistatic filter mediums ensures safe operation by preventing static build-up within the equipment.

Uniform Granulation: A multi-fluid spray gun is used for atomizing the binding agent, ensuring a uniform spray of particles and significantly increasing the quality and yield of the final product.

Easy Cleaning and Compliance: Designed with no dead corners, the equipment allows for easy and efficient feeding, discharging, and cleaning, meeting GMP standards for hygiene and safety.

Application of Fluidized Bed Granulator

Pharmaceuticals: Ideal for drug granulation and coating, it is used for producing tablet particles, granule particles, and capsule particles.

Coating Applications: Suitable for coating particles and pills with color preparation, slow-release coatings, films, and enteric coatings.

Food Industry: Employed in the granulation and coating of food products such as granulated sugar, coffee, cocoa powder, cream, juice powder, amino acids, sauces, and puffed foods.

Agricultural and Industrial Uses: Utilized in the production of pesticides, paint pigments, and the dry granulation of powders, granules, and block materials.

Parameter

Model | Capacity (L) | Diameter (mm) | Production Capacity (L) | Steam consumption (kg/h) | Air Compression (m3/min) | Host weight (kg) |

5 | 22 | 400 | 4-6 | 23 | 0.6 | 300 |

15 | 45 | 550 | 10-18 | 42 | 0.6 | 700 |

30 | 100 | 700 | 15-36 | 70 | 0.9 | 900 |

60 | 220 | 1000 | 30-72 | 141 | 0.9 | 1100 |

Model | Capacity (L) | Diameter (mm) | Production Capacity (L) | Steam consumption (kg/h) | Air Compression (m3/min) | Host weight (kg) |

5 | 22 | 400 | 4-6 | 23 | 0.6 | 300 |

15 | 45 | 550 | 10-18 | 42 | 0.6 | 700 |

30 | 100 | 700 | 15-36 | 70 | 0.9 | 900 |

60 | 220 | 1000 | 30-72 | 141 | 0.9 | 1100 |