The rotary evaporator is used to concentrate, crystallize, separate and recover heat-sensitive new materials. It is a necessary experimental instrument for chemical industry, pharmaceuticals, universities, colleges and scientific research units. The 2L rotary evaporator is one of our best-selling models. It The capacity of the rotating bottle is 2L, and the capacity of the receiving bottle is 1L. It is a small rotary evaporator. Our 2L rotary evaporator models are: RE-201D rotary evaporator, RE-5299 rotary evaporator, RE-2000ABE rotary evaporator, N-1100D rotary evaporator.

2L rotary evaporator features

1) It is well sealed and can maintain high vacuum.

2) The mechanical parts are made of stainless steel and aluminum alloy, which are anti-corrosion and durable.

3) The glass parts are made of high temperature resistant high borosilicate glass, which is corrosion resistant.

4) The rotary evaporating flask is easy to install and set up.

5) The rubber connecting pipe and other parts are easy to replace.

6) The feeding valve can realize non-stop feeding.

7) The transmission system adopts frequency conversion speed regulation, which is convenient and reliable.

8) The water bath can be adjusted up and down according to the needs.

Precautions for use of 2L rotary evaporator

1) The solvent capacity in the rotary evaporating flask should usually not exceed 50%.

2) The heating medium must be injected into the oil bath before it is powered on, and it must not be dry-fired.

3) When the vacuum degree is insufficient, check whether each interface is sealed.

4) When installing glass fittings, handle them with care, and clean and dry them before installation.

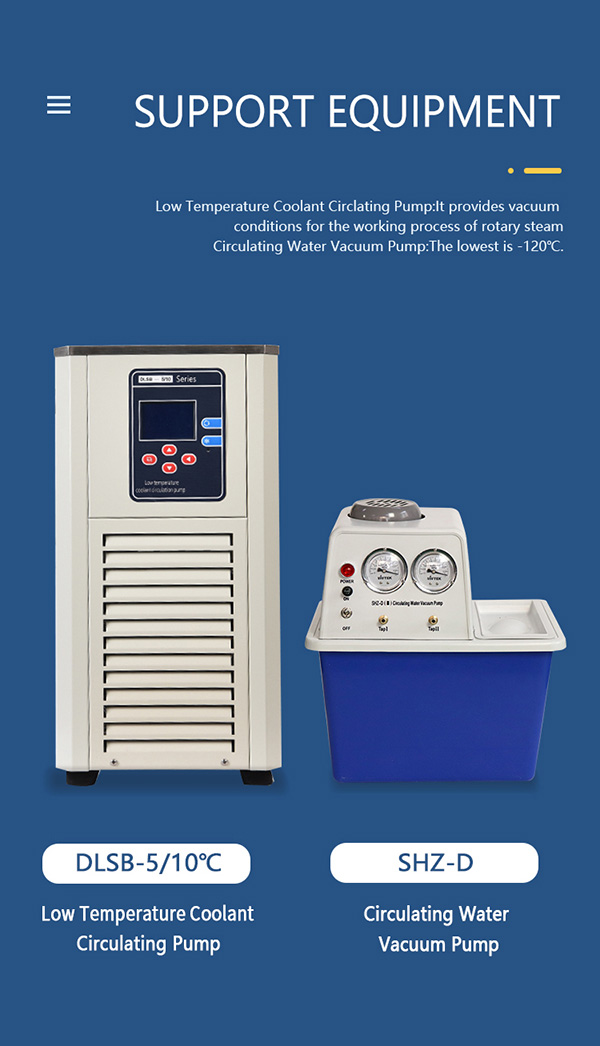

Supporting equipment for 2L rotary evaporator

Circulating water vacuum pump: It uses water as the medium to provide vacuum conditions for the rotary steaming process. The 2L rotary evaporator is a small rotary steamer. We recommend using the SHZ-D desktop circulating water vacuum pump.

Low temperature coolant circulation pump: It adopts the principle of mechanical refrigeration to provide a circulating refrigeration source for the reaction substances, the lowest temperature can reach -120°C, and the capacity ranges from 5L to 100L. For 2L rotary evaporator, it is recommended that you use a 5L cooling chiller.

2L Rotary Evaporator Operating Instructions

1) Assemble the machine, connect the cryopump and vacuum pump, the vacuum tube of the vacuum pump is connected to the interface in the middle of the rotary condenser, and the silicone tube of the cryopump is connected to the interfaces on both sides of the condenser;

2) Turn on the cooling chiller switch, first turn on the cycle button, and then turn on the refrigeration button.

3) Turn on the switch of the circulating water vacuum pump, start vacuuming, and observe the reading of the vacuum gauge. When the vacuum gauge stays at the maximum vacuum for a period of time, it indicates that the equipment is well sealed and can start feeding.

4) Pump the rotary evaporator into a negative pressure state, and connect the feeding valve with the added sample with a hose;

5) Open the feeding valve, the sample will be directly pumped into the rotary bottle, and close the feeding valve after the feeding is completed.

Maintenance of 2L rotary evaporator

1) Check the instrument carefully before use to see if the glass bottle is damaged and whether the interfaces are consistent, and pay attention to handling the glass parts with care.

2) Use a soft cloth or paper towel to wipe each interface, and then apply a little vacuum grease. After the vacuum grease is used, it must be covered to prevent dust from entering.

3) Each interface should not be screwed too tightly, and should be loosened regularly to avoid the connectors being unable to be unscrewed due to long-term locking.

4) After turning on the power switch, let the machine gradually accelerate from slow to fast. When stopping, make the machine stop, and then turn on the light switch.

5) The PTFE switch should not be screwed too tightly, as it may easily damage the glass.

6) After each use, use a soft cloth or paper towel to wipe off various oil stains, stains, solvent residues, etc. remaining on the surface of the machine to keep the machine clean.

7) Loosen each PTFE switch after the machine stops, otherwise the long-term locked state will deform the PTFE piston.

8) Clean the sealing ring regularly, first remove the sealing ring, check whether there is dirt on the shaft, then wipe it with a soft cloth or paper towel, apply a little vacuum grease, and reinstall it to keep the shaft and the sealing ring lubricated.

9) The motor part is not allowed to enter the water.

Parameter

Model | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range | Evaporation Rate(H2O) | Voltage | Lifing Height(mm) |

RE-2000B | 40 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~140 |

RE-5299 | 30 | 1500 | RT~99℃ | ≥1L/h | 220V/50HZ | 0~150 |

RE-201D | 40 | 1200 | RT~399℃ | ≥1L/h | 220V/50HZ | 0~150 |

Model | Rotating Motor(W) | Water(Oil) Bath Power(W) | Temperature Control Range |

RE-2000B | 40 | 1500 | RT~99℃ |

RE-5299 | 30 | 1500 | RT~99℃ |

RE-201D | 40 | 1200 | RT~399℃ |