Short-path distillation equipment is a special technology for liquid-liquid separation. The mean free path of vapor molecules is greater than the distance between the evaporation surface and the condensation surface under high vacuum conditions, so the difference in the evaporation rate of the components in the feed liquid can be used to separate the liquid mixture.

How to use a short path still:

The material is added from the top of the evaporator, continuously and evenly distributed on the heating surface through the material-liquid distributor on the rotor, and then the film scraper scrapes the material into a thin turbulent liquid film. and push down in a spiral. During this process, the light molecules escaping from the heating surface condense into a liquid after a short distance on the built-in condenser with almost no collision, and flow down the condenser tube and pass through the evaporator at the bottom of the evaporator. The discharge pipe is discharged, and the residual liquid, that is, heavy molecules, is collected in the circular channel under the heating zone, and then flows out through the discharge pipe on the side.

1. Turn on the main power.

2. Open the low temperature thermostat, press the freeze button and cycle button on the thermostat and set the temperature, let the temperature drop to the set value and stabilize.

3. Turn on the power of the rotary vane pump and observe whether the rotary vane pump is running normally, so that the equipment is in a vacuum state first.

4. Turn on the oil pump to circulate the hot oil.

5. Turn on the electric heating power and set the heating temperature.

6. Turn on the stirring paddle motor, make the stirring paddle run, and observe whether it is normal.

7. Put in the material, pay attention to the liquid level.

8. Open the material outlet valve.

9. Open the injection valve.

10. Pay attention to the liquid level of the material, and add the material in time.

11. After the distillation of the material is completed, cool down.

12. When the temperature drops to a safe value, turn off the rotary vane pump.

13. Turn off all power and clean up the operation site.

How a short path still works:

The driving force of the steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the steam to flow. Operating at 1 mbar and requiring a short distance between the boiling surface and the condensing surface, a still made according to this principle is called a short path still. Short path stills (molecular distillation) have a built-in condenser opposite the heating surface and bring the operating pressure down to 0.001 mbar.

Application fields of short-path stills:

1. Petrochemical: separation and refining of crude oil, such as: preparation of low vapor pressure oil, high viscosity lubricating oil, separation of hydrocarbons, refining of residual tar, base oil, bright stock, vaseline, etc. Distillation Regeneration of Heavy Oil Distillation Vacuum Residue Recovers paraffins from heavy oil. Energy and environmental protection waste oil regeneration biodiesel.

2. Chemical industry: refining of chemical intermediates and purification of surfactants, such as: fatty acids, fatty acid amides, fatty alcohols, surfactants, dimer acids, polyamide resins, phenolic resins, polyurethanes, isocyanates, Epoxidized oil, etc. Distillation of chemicals, such as: polymer alcohols, alkanes, polyols, milk amines, etc.

3. Pharmaceutical industry: purification of pharmaceutical intermediates and extraction of pharmaceutical products from natural substances: vitamin E, vitamin A, glucose derivatives, amino acid lipids, lecithin, β-carotene, etc.; separation of mixed oils: such as stearin Acid monoglyceride, lauric acid monoglyceride, propylene glycol, etc. recover active ingredients from mother liquor; concentration and purification of organic acids; drying of synthetic resins; dehydration and desolvation of polymer substances.

4. Coating industry: Molecular short-path distillation can remove the solvent and TDI monomer from the polyurethane prepolymer.

5. Cosmetics industry: Removal of pesticides in cosmetic bases; synthesis of flavors and fragrances and purification of natural flavors and fragrances, such as the refining of rose oil, cinnamon oil, vetiver oil, citronella oil, and pineapple oil.

The main features of short-path distillation:

1. Operate at a temperature far below the boiling point of the material, so that the residence time of the material is short, which is conducive to the separation of easily oxidized materials with high boiling point and high heat sensitivity;

2. Effectively remove substances in liquids such as organic solvents and odors, which is a very effective method for desolventizing liquids after solvent extraction;

3. The product can be evaporated to remove other impurities, and multi-stage separation can separate more than two substances at the same time;

4. The vacuum degree in the distillation process is very high, which can reach below 0.1pa, and a high degree of vacuum can also be obtained inside. Generally, molecular distillation is carried out at very low pressure, so the material is not easily damaged by oxidation;

5. The distillate film is thin, the heat transfer efficiency is high, and the thickness is less than 0.5 mm;

6. High degree of separation, molecular distillation can separate conventional substances that are difficult to separate;

7. No boiling and bubbling. Molecular distillation is a process of free evaporation from the surface of a liquid layer. It is carried out under low pressure, and there is no dissolved air in the liquid, so the whole liquid will not boil, and there will be no air bubbles during the distillation process;

8. Provide customers with a variety of specifications to choose from, suitable for customers to conduct small tests and pilot tests. For larger evaporation area specifications, it can be customized according to customer requirements;

Short path distillation FAQ:

Short-path distillation equipment is a special liquid-mixture that separates the liquid mixture by using the difference in the evaporation rate of the components in the material and liquid under the high vacuum state, so that the mean free path of the vapor molecules is greater than the distance between the evaporation surface and the condensation surface. Liquid separation technology. It is not only used in the field of medicine, petroleum, but also widely used in the field of food.

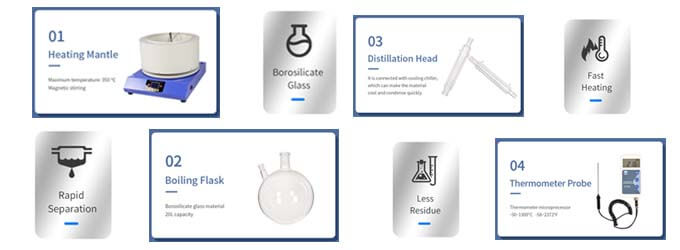

1. What are the components of short path distillation?

Heating part (electric heating mantle), evaporating flask, distillation elbow, four-neck flask, receiving flask, cold well.

2. What is the function of the cold well of short path distillation?

Filter some gases, liquid gases, impurities, and enter the vacuum pump to pollute the vacuum oil.

3. What is the role of short path distillation?

The evaporative extraction of the material was carried out under vacuum.

4. What are the types of film scrapers for short-path distillation and how to choose?

Rolling film type, sliding wiper type, hinge wiper type, suitable film scraper can be selected according to the viscosity and processing properties of the material.

5. What is short path distillation?

The driving force of the steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the steam to flow. Operating at 1 mbar and requiring a short distance between the boiling surface and the condensing surface, a still made according to this principle is called a short path still.

6. What is the distillation process of short path distillation?

The molecules diffuse from the main body of the liquid phase to the evaporation surface, the molecules evaporate freely on the surface of the liquid layer, the molecules fly from the evaporation surface to the condensation surface, and the molecules condense on the condensation surface.

7. What is the maximum vacuum that short path distillation can achieve?

The maximum vacuum degree is 0.098Mpa.

8. What are the preparations for short-path distillation before starting up?

First turn on the cooling water circulating pump, adjust the temperature and pre-condensate, turn on the rotor of the film scraper, and test it to see if it rotates evenly and continuously, and secondly, listen to whether there is any noise in the sound of the scraping film.

9. What should I do if the flow rate of the injector is out of control in short-path distillation?

At this time, after tightening the control valve clockwise and there is no obvious improvement, remember not to use excessive force on the knob, only turn off the vacuum pump, do not perform other operations, and promptly contact the person in charge of the instrument or full-time personnel for handling.

10. What should I do if the sound of the wiper of the short-path distillation is abnormal or the rotation speed is uneven and continuous?

First, turn off the heating, rotation and vacuum pumps, and contact the person in charge of the instrument or professional personnel for processing.

11. What should I do if the separation effect of short-range molecular distillation is not good?

Select the appropriate evaporation temperature, the material flow rate is too high, affecting the separation efficiency, there are impurities in the material, the thinner and more uniform the evaporation liquid film, the larger the summer cover area, the better the distillation effect.

12. What are the precautions for using short-path distillation?

It is not advisable to run at high speed with no load, keep the speed regulation and the motor dry, because the life of the electrical box and the surrounding humidity and temperature have a great influence, please avoid the impact damage to the glass by hard objects such as watches and rings when operating the instrument.

13. What materials are mainly used in short-path distillation equipment?

The main raw materials produced by the short-path distillation kit are borosilicate glass, polytetrafluoroethylene, 304 stainless steel and other materials. They all have good chemical resistance and are very good laboratory distillation equipment.

14. What is the heating form of the short path distillation unit?

The short-path distillation unit uses an electric heating mantle to provide the heat source for the entire short-path distillation system. The electric heating mantle can be heated up to 250°C under the condition that the whole equipment is under negative pressure. This heating mantle has a magnetic stirring function, which helps the contents of the reaction flask to be distilled out more quickly.

15. What models do you have for short path distillation?

SPD-2L, SPD-5L, SPD-10L, SPD-20L. Customization is acceptable.

16. What are the applications of short path distillation?

As a hot product of our company, short-path distillation is committed to high efficiency and low cost. At the same time, this short-path distillation unit is widely used in pharmaceutical, laboratory fractionation and purification, food and beverage, essential oil and other industries.

17. What is laboratory short path distillation?

Short path distillation is a distillation technique that involves the flow of distillate over a short distance, usually just a few centimeters, usually under reduced pressure.

18. What are the characteristics of the magnetic stirring heating mantle?

Provides a large heating area, uniform heating, and rapid heating. Brushless DC motor, stable performance, low noise, long life, no spark.

19. How does short path distillation work?

In a short path distillation unit, a liquid solution or emulsion is suspended in an evaporating flask, which is connected by a short feed to a condenser or cooling device. The evaporating flask was placed in a heating mantle that gradually raised the temperature of the solution to a predetermined boiling point, thereby promoting the evaporation of the different compartments of the solution.

20. What are the applications of short-path distillation?

It can replace the conventional falling film evaporator for the distillation, purification, concentration and decolorization of petrochemical and chemical products; it is especially suitable for the distillation and purification of heat-sensitive and easily oxidized chemical industrial products; it can also be used for the distillation and separation of high-boiling point products.